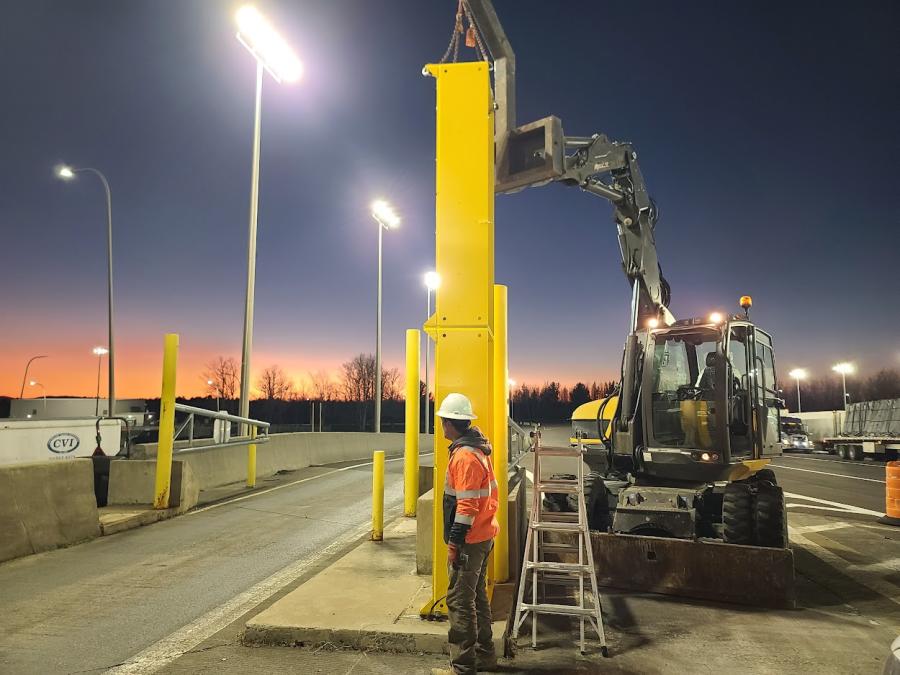

Equipped with an Engcon tiltrotator and grapple, Canonica Land Works’ Mecalac 11MWR easily manipulates large tree trunks.

(CEG photo)

Increasingly, contractors across the country are adding compact wheeled excavators to their fleet with a variety of unique applications. Here are two contractors that are realizing incredible benefit from using Mecalac equipment.

Kobo Utility

Kobo Utility in Cape Cod, Mass., categorizes itself as a heavy electrical contracting company that also does a lot of utility work. Kobo has a broad reach with offices in Massachusetts, Florida and California.

"We started the process of replacing tractor loader backhoes in our fleet with wheeled excavators years ago," said Kevin O'Neil, president of Kobo Utility. "At that time, the excavators that were available to us were not an ideal solution. They were big and somewhat cumbersome. What we were really on the hunt for was a wheeled excavator that was under 30,000 pounds.

"I had been doing some research and became aware that Mecalac produced a machine that fit the category that I was looking for and initially I was disappointed to find out that they were not being brought into the United States. That all changed in 2016 when Lorusso Heavy Equipment in Massachusetts became the first dealer in the country. We purchased a Mecalac 9MWR weighing 17,000 lbs.

"With the Mecalac's unique design, each time I added a Mecalac to the fleet, I was not only gaining an excavator, but also a telehandler with a set of forks, and a skid steer because of the Mecalac's ability to push material. We were able to reduce our equipment inventory with every Mecalac purchase.

"It was a bit of a process, but it didn't take long for our operators to prefer to have a Mecalac on the job versus the equipment that we were replacing. Another bonus that we discovered was transportation. To haul a tractor loader backhoe to a job site, the backhoe took up 30 feet on the trailer. All folded up the Mecalac only took 9 feet.

"Surprisingly, we found that the Mecalac, which we were using as a multi-functional piece, did each job assigned to it better than the purpose-built machine that it was replacing. It dug better than an excavator, it lifted better than a telehandler and it pushed better than a skid steer.

"In comparing the Mecalac to a telehandler, you can pick up heavier materials, lift them straight up in the air, spin around 360 degrees and drop it directly behind you. You can never do that with a telehandler. A skid steer loader gives you terrible visibility and tears up a job site. With a Mecalac, you just pull into the pile, lift up the load and pull away. Your view is elevated, it's perfect, and the wheels do no surface damage at all.

"When I compare the working capacity of a tractor loader backhoe to the Mecalac MWR, the Mecalac digs better and loads better than a tractor loader backhoe and takes up far less space. It's a win-win. Loading the truck is so much easier with the Mecalac. The loading bucket has full rotation and higher reach, and the truck can be parked virtually anywhere. With Mecalac's unique coupler design you can change out from the digging bucket to the loading bucket literally in seconds without leaving the cab."

The versatility of the Mecalac has made Kobo Utility's transportation much simpler — one trailer, one machine and a handful of attachments that would typically include a narrow digging bucket, a 36-in. digging bucket, a loader bucket and a skid steer plate that allows it to add a couple of attachments like a set of forks and a sweeper.

"When we work on a project with a large footprint like an airport, the Mecalac becomes a huge timesaver. We are able to quickly dispatch the machine when we have to move from one end of the site to the other at 20-25 miles per hour. The hydraulic flow is extraordinary, much better than any skid steer we have ever owned or any excavator in the same size category. Among other things, that hydraulic flow converts to great hydraulic attachment performance."

Kobo Utility is equally pleased with its dealer, Lorusso Heavy Equipment.

"Lorusso has done an astounding job supporting us, and very importantly, as we have moved our fleet all across the country, we have found that the other Mecalac dealers are equally supportive. The technicians are properly trained and typically the parts are in inventory."

Canonica Land Works

Canonica Land Works based in Chelsea, Vt., specializes in land-based excavation work such as stone wall construction, trail maintenance and stream reconstruction. The company currently uses a Mecalac 11MWR weighing 24,000 lbs., but this was not its first Mecalac purchase.

Eight years ago, Ben Canonica purchased the first Mecalac 10MCR multi-function excavator that was brought into the United States from Europe. The Mecalac 10MCR, which is actually a hybrid combination of an excavator and compact track loader met their needs. "There obviously would not have been a second purchase unless the original purchase of the 10MCR had gone well," Canonica said.

Canonica Land Works is involved in a lot of environmentally sensitive work, much of it in the Vermont countryside. A few years ago, it became evident that an invasive species from Asia called the "emerald ash borer" was settling into the woods of Vermont and doing massive tree damage, which would result in the necessity to have thousands of ash trees removed, many of them along the roadside. This led Canonica to the conclusion that he would be well situated to be hired for that type of work if he purchased a compact wheeled excavator.

Canonica Land Works also does a lot of work on gravel roads and dirt trails where a rubber-tired machine would do less damage to the road surface. From his previous experience with the Mecalac 10MCR, he had a very high degree of confidence in the technology and the product support that comes along with buying the Mecalac product.

According to Canonica, "Everything about working with the Mecalac machines is innovative, but the one thing that probably stands out the most to me is the unique design of their three-piece multi-segmented boom. It allows you to dramatically increase your lifting capacity and digging flexibility by bringing the main boom back next to the cab.

"You can almost raise and lower the load like a forklift with the intermediate boom. You can also position the boom to work around obstacles or under obstacles, but what really stands out the most is the lifting capacity."

Canonica had an immediate need that gave him an opportunity to rent a Mecalac 11MWR for a few months to make sure it was going to meet his expectations: he needed to do some riverbed restoration work from severe flooding that had happened locally and to access the site, he needed to traverse some agricultural areas and get in and out of the river area doing as little damage as possible.

"Everything about the machine impressed me. It was exactly what I would expect from a Mecalac. Very stable, good maneuverability and as I had hoped, very little impact on the land surfaces that the machine traversed as long as we were in reasonably dry conditions."

At the end of the rental period, Canonica pulled the trigger on the purchase.

The attachments for his 11MWR were virtually interchangeable with his Mecalac 10MCR, which included an Engcon tiltrotator, a digging bucket, a ripper, a sorting grapple, a Rotastar screening bucket, a GMK multi-grab, a GMK tree shear, a Shearex mulcher and a Rammer plate compactor. After the purchase of the Mecalac 11MCR, the predicted ash borer work and related tree removal came to fruition, some of which occurred on extremely hot days, which would have made the asphalt particularly susceptible to surface damage.

Canonica also started using the Mecalac for tree removal in the forest, where he found the machine to be particularly adept.

"The four-wheel steering gives great maneuverability; you really notice it in tight spaces. The other thing you notice with the wheeled machine versus the tracked machine is that the wheels give you a substantially more comfortable ride."

Canonica wasn't sure if he would keep his Mecalac 10MCR after the purchase of the Mecalac 11MWR, but in the end analysis, he found that certain applications were more desirable for a tracked machine, while others called for the wheeled machine. Keeping both just made sense.

"This year we did a lot of stonework with the wheeled machine. A lot of projects were right at the end of homeowner's driveways and gravel roads, so often we were set up right on the hard road or the property owner's property. It was very noticeable how quick and comfortable the machine was and that we weren't tearing up any surface area at all.

"We are in a very rural area, so it's not often that I get the benefit of driving the machine from project to project and eliminating the hauling process. But, when we can, it's certainly nice to take advantage of that. I do appreciate how compact the machine is and it's great to be able to load up the excavator and all of our attachments into a single load." CEG

Read more about Mecalac wheeled excavators.

Today's top stories