The site is located in the Amber Park area and serious coordination and drawings were required early on.

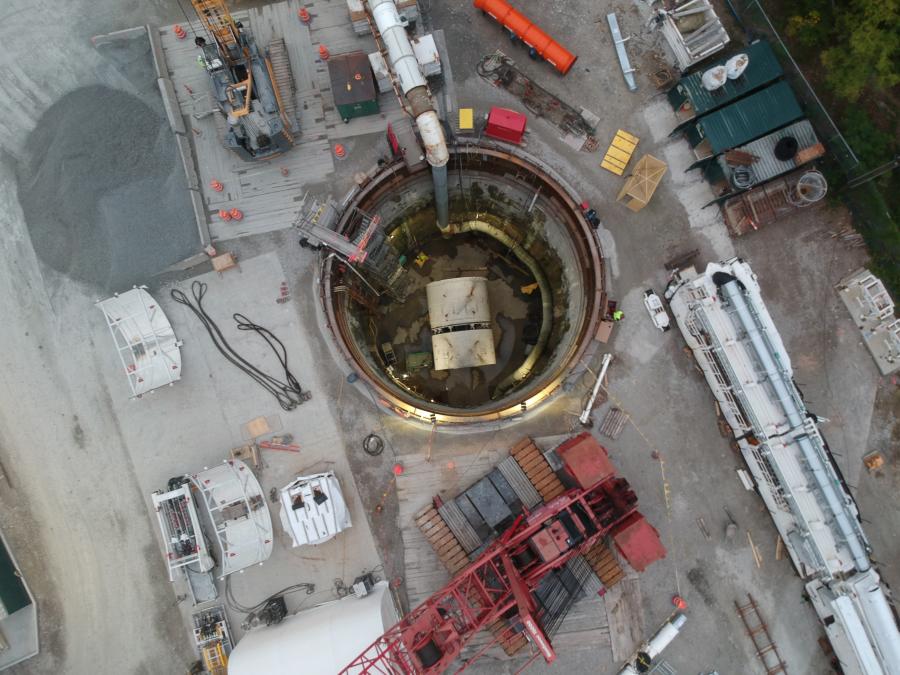

(McNally/Kiewit DVT JV Photo)

Part of the Northeast Ohio Regional Sewer District's (NEORSD) Project Clean Lake, the $142.3 million Doan Valley Storage Tunnel project (DVT) has McNally/Kiewit DVT JV (McNally Tunneling Corp. and Kiewet Corporation) constructing three tunnels to help deal with combined sewer overflows (CSO) and have it treated.

"Our program is geared toward meeting Clean Water Act standards and addressing water-quality issues," said the project web page. "The DVT system will help control overflows at 11 locations along Doan Brook, from Shaker Heights to Lake Erie. This control will contribute to Project Clean Lake's overall goal: capturing 98 percent of all combined sewer flows for treatment."

Construction began in July 2017 and will be completed in early 2022. The crews are boring three tunnels - nearly 4 mi. of rock tunnel under the city of Cleveland: the 10,000-ft. long (18-ft. diameter) DVT, the 3,000-ft. (8.5-ft. diameter) Martin Luther King Conveyance Tunnel (MLK), and the 6,300-ft. (8.5-ft. diameter) Woodhill Conveyance Tunnel (WCT).

The DVT's main surface-level construction sites are near Superior Avenue and East 115th Street; Ambler Park, Woodhill and Baldwin roads; the intersection of Chester and Euclid avenues Stokes Boulevard; and close to the Cleveland School of the Arts near the intersection of Carnegie Avenue, Martin Luther King, Jr. Boulevard. and Stearns Road.

"The project will reduce CSO by 365 million gallons annually, and decrease flooding during rain events," said Jennifer Elting, NEORSD's senior public information officer. This project is part of a 25-year program to control the amount of raw sewage discharged into area waterways, including the Cuyahoga River and Lake Erie, during heavy rains. PCL will reduce combined sewer overflow (CSO) from 4.5 billion gallons to 500 million gallons by 2036."

The NEORSD is completely ratepayer-funded, and the financing for the project may be state loan fund, one that will be repaid by the utility. The DVT is one part of a federally-mandated consent decree. Project Clean Lake is a Sewer District program geared toward meeting Clean Water Act standards and addressing water-quality issues.

McMillen Jacobs Associates is the design engineer for the project, and is partnering with Trim.

"The tunnels are expected to last generations as maintenance is a huge part of our work," said Elting. "We spend $50 million annually on maintenance alone. We have interceptor sewers that are more than 100 years old still in operation. We sometimes have to relocate utilities, but those are closer to the surface. Generally speaking, DVT is so far underground that we're mining through solid rock and there aren't impacts. The biggest impact we have is lane closures near our various shaft site locations, as well as truck routes when we're hauling tunnel spoils.

"Project Clean Lake began in 2011 and DVT was part of the program's plan since way before that," she said. "Our Board of Trustees authorized our entering into a design contract with Jacobs Associates/Wade Trim JV at the Jan. 15, 2015 meeting."

Construction impacts — long-term and short-term — include lane closures and traffic pattern changes (including bikeways); noise and vibration; dust, dirt, and/or mud; and disruption to community aesthetics, including tree removal. The NEORSD is providing regular updates to the community.

The westernmost lane of Martin Luther King, Jr. Boulevard. near Ambler Park between North Park Boulevard. and the bridge north of Ambleside Drive will be closed until November 2021.

"We plan in advance to inform local residents far in advance of our major construction projects," said Elting. "Lake Erie is Greater Cleveland's greatest natural resource and our customers definitely appreciate our efforts to keep our Great Lake great." In addition, we are active on social media and regularly interact with our customers and anyone interested in our work."

In 2018 heavy rains flooded a construction site for the WCT at Ambler Park near the intersection of Martin Luther King, Jr. and Ambleside drives, which filled the tunnel that had a tunnel boring machine inside it and led to some debris pouring onto the streets.

"This is not the only area that experienced flooding, and our stormwater inspectors are responding to the needs of our member communities," said Frank Greenland, director of Watershed Programs. "Many creeks and streams flooded and we are inspecting the stream network to determine appropriate maintenance needs such as clearing debris from culverts."

McNally/Kiewit DVT JV has completed the tunnel drive the WCT and crews have installed about 75 percent of the concrete pipe. For the DVT tunnel, the large one, about 35 percent of the mining has been completed. The drive for the MLK will start once the DVT mining is finished.

The JV self-performed the excavation of the six tunnel shafts,

"We immediately met the challenge of assembling a great team that has meshed," said Chris Lynagh, the JV's project manager and a McNally employee. "Another is basically keeping our equipment moving every day — we're constantly maintaining the equipment, making sure everything is greased, oiled and lubed. It's an ongoing battle because there is a lot of equipment in the tunnels. We're also mining these tunnels in a relatively small site compared to other projects we've been on. The sites are very congested and we have about 200 truckloads of material coming in and out of it daily."

This is a year-round operation, with the DVT tunnel work based on three shifts per day, Monday to Friday, with occasional Saturdays that have mechanics repairing the TBMs and other equipment.

Explosives could not be used to drill the shafts due to the site's proximity to University Circle, hospitals and underground utilities. The shafts were excavated using excavators with hydraulic hammers.

The site is located in the Amber Park area and serious coordination and drawings were required early on.

"We don't have the leisure of extra space," said Lynagh, "and even parking is an issue for each shift. We had to find designated parking space. Up the hill from us is the Baldwin Treatment Plant, one of the larger water treatment plants for Cleveland and two of their main intake for it go right under our site. A big concern early on, with all our activities, was not to load too much weight on the fragile and old utilities."

After cutting through the top layer of soft ground with rib and liner plates to create the shafts, crews encountered the Chagrin and Ohio shale. Once excavated, rock bolts, welded wire mesh and shotcrete were used to line the shafts for ground support.

"Very detailed planning was critical," said Lynagh, "and it was time consuming, but the mining is going good and we're seeing the fruit of our labor. We have a good relationship with the NEORSD, and we've done quite a few projects for them over the last eight years, including the Euclid Creek Tunnel — one of the flagship elements of Project Clean Lake.

As the shafts were being prepared — some of work occurring in cold winter months through the use of heating via water and air lines, so were the two TBMs. The large 20.75-ft. Herrenknecht AG was manufactured and assembled in Germany and shipped to the Port of Cleveland via the Atlantic Ocean and the Great Lake, with the disassembled parts shipped by truck to the work site. It took nearly eight months to manufacture and deliver the TBM. For the two smaller tunnels, a McNally-owned 12-ft. Robbins TBM, purchased from the Robbins Company in the 1970s, was shipped to the site.

The JV sent its heading engineers, who supervise the tunneling operations shifts, for several months to Germany to learn how to operate, assemble and disassemble and repair the TBM, as well as four management staff for two weeks.

"We do a lot of repairs as we go," said Lynagh. "You have to constantly work that into the schedule. For that we have daily, weekly and monthly checklists, and we have a mechanic on each shift. TBMs are more electronic and computer-based. The older Robbins TBM is mostly hydraulics. The local Chagrin shale is very soft rock and the TBMs we have are rock machines — it's like cutting butter for them."

Conveyer systems are not being used to remove the debris. For the large TBM, two 35-ton locomotives (owned by McNally), along with 16-cu.yd. muck boxes are being used, and for the smaller TBM, 15-ton locomotives and 8 cu. yds. muck boxes are employed.

The Robbins TBM was assembled within a few weeks, while the Herrenknecht AG TBMs took several months.

The WCT tunnel drive has been completed, and mining for the DVT tunnel began last February.

"To line the two smaller tunnels," said Lynagh, "we're using ribbon legging — steel ribs rolled to the diameter of the bore and the legging boards are put between the ribs to support the ground. Our final lining is 8.5-foot IB concrete pipe that we place in the tunnel with a hydraulic-driven pipe carrier."

For the larger tunnel, a segment fully lined tunnel, the lining is installed as new areas are mined.

"Five pieces of concrete come together to form a complete ring," said Lynagh.

Each shift has quality control personnel, including tunnel walkers to ensure that everything is done correctly.

This has been the fourth or fifth joint-venture between the two companies.

"It's always a slightly different team every time," said Lynagh, "but we rapidly become a team and start working together. Everything is split between the companies — responsibilities, monetary items, and risks. We share equipment and whatever we have available to get the job done."

Lynagh is assisted by Project Engineer Lance Jackson (McNally), Tunnel Manager Martino Scialpi (Kiewit), and Tunnel/General Supervisor Joe Teter (McNally).

Scialpi, who worked for Robbins until early 2017, oversees the TBM operations.

"The mining operations are going very smoothly — the TBM is performing very well," he said. "All three crews are boring between 25 and 35 feet per shift. Recently one crew completed 45 feet in eight hours, and our best day was 110 feet. We're not breaking industry records, but what makes us happy is the consistency we've achieved in very few weeks since mining started, averaging the 85 feet per-day we anticipated. The main challenges here are on the logistics side. The main job site includes two shafts and two tunnels; bringing construction materials in and removing the spoils from both headings at the same time requires a lot of coordination.

"In my experience," he said, "both JV partners are working in sync and there are no issues. This reflects on the progress that the crews are making on a daily basis, and this is no surprise as both companies have successfully worked together on previous projects."

Currently onsite are 72 unionized employees — equipment operators from Local 18 and laborers from Local 860, 25 full-time staff from the JV, and about 20 people from subcontractors, which include: Northstar Contracting for concrete work, Chieftain Truck for material hauling, and Digioia Suburban for open cut excavations.

The shaft excavation and drilling operations will result in the removal of 320,000 tons of earth and rock. Chieftain Truck, which is removing the materials, has a dump site that is 15 minutes away from the shaft sites.

The shale can be used as fill and backfill.

A Liebherr 885 crane lifts the buckets to the surface.

New materials to line the tunnels and build the infrastructure include 37,000 tons of precast concrete segments for lining the larger tunnel, 14,000 tons of precast concrete pipes for lining the smaller tunnel, and more than 5,000 tons of cement for backfill grout.

In addition to the TBMs, the J.V. is using: cranes, dozers, excavators, loaders and other standard construction equipment.

"We experience the normal wear and tear with our equipment," said Lynagh. "You've got to keep things greased and oiled, otherwise you're going to have issues. The cranes are working around the clock, so constantly maintaining them and doing inspections is critical. They are also a high risk piece of equipment because when you're lifting stuff in and out from a 100-foot depth, you don't want your crane to fail on you — otherwise you're dead in the water. It's critical have good mechanics that know the work and have experience with the equipment, and we have experienced mechanics."

The JV purchases and rents equipment from dealerships such as Ohio CAT — loaders, excavators, etc.; Liebherr Crane; Murphy Tractor and Equipment for NPKce hammers for its CAT excavators to get through rock and shale; Valco Equipment for manlifts and similar equipment; United and Sunbelt Rentals; and Lincoln Electric for welding equipment. The grout plant is from Team Mixing Technologies; cement and bentonite silos are from Belgrade, Serbia, and the cooling plant is from Delta Cooling.

"We try to get good deals on our equipment," said Lynagh. "We like to get equipment that is used, but not overly used. For example, one of our loaders was previously working at an airport and had very low hours on it."

Lynagh appreciates the efforts of the dealerships to support the project.

"Whenever we have a major [issue] with one of our cranes," he said, "ALL Crane or General Crane come out and assist us, and it's the same with Ohio Cat."

The project is allowing the JV partners to hone the crews' skills.

"We're constantly training and moving our staff up," said Lynagh. "The biggest asset that we have is our employees and making sure that senior management experience is passed on to younger employees to ensure that McNally is a prominent company in the tunnel industry for years to come."

Safety is constantly stressed and a recent Safety Week was utilized to bring the crews together to discuss a variety of issues. Craft employees were given the opportunity to sit down with management and executives from the company and discuss safety on the job site and the industry.

"We also have 90-day schedule meetings to go over what will happening and have everyone on the same page," said Linagh, "The crews are proud of their work and are aware of the big picture of the project — keeping Lake Erie clean and having a healthy environment in the Cleveland area."

CEG

Irwin Rapoport

A journalist who started his career at a weekly community newspaper, Irwin Rapoport has written about construction and architecture for more than 15 years, as well as a variety of other subjects, such as recycling, environmental issues, business supply chains, property development, pulp and paper, agriculture, solar power and energy, and education. Getting the story right and illustrating the hard work and professionalism that goes into completing road, bridge, and building projects is important to him. A key element of his construction articles is to provide readers with an opportunity to see how general contractors and departments of transportation complete their projects and address challenges so that lessons learned can be shared with a wider audience.

Rapoport has a BA in History and a Minor in Political Science from Concordia University. His hobbies include hiking, birding, cycling, reading, going to concerts and plays, hanging out with friends and family, and architecture. He is keen to one day write an MA thesis on military and economic planning by the Great Powers prior to the start of the First World War.

Read more from Irwin Rapoport here.

Today's top stories