Retracting the cylinders will prevent the rods from rusting and collecting dust, which damages the cylinder rod seals.

Are you done with road construction projects for the year? Are you nearly finished? If so, it is time to think about getting your concrete dowel pin drills and hydraulic paving vibrators ready for next season.

In order for a contractor to get the most from dowel drills on a springtime job site, the drills must be properly stored over the winter. Likewise, vibrators need attention from their manufacturer in the offseason to maximize contractor productivity when paving resumes.

Drill and vibrator manufacturer Minnich Manufacturing offers the following tips on caring for your drills and vibrators this winter to maximize performance, control costs and extend machine life.

Store Your Drills Properly

Adhering to the dowel pin drill manufacturer's long-term storage recommendations can help prevent rust that impacts equipment performance, leads to costly downtime and shortens drill life span.

Following are six tips for construction companies to consider when storing dowel-pin drills for long periods of time, generally defined as 60 days or more:

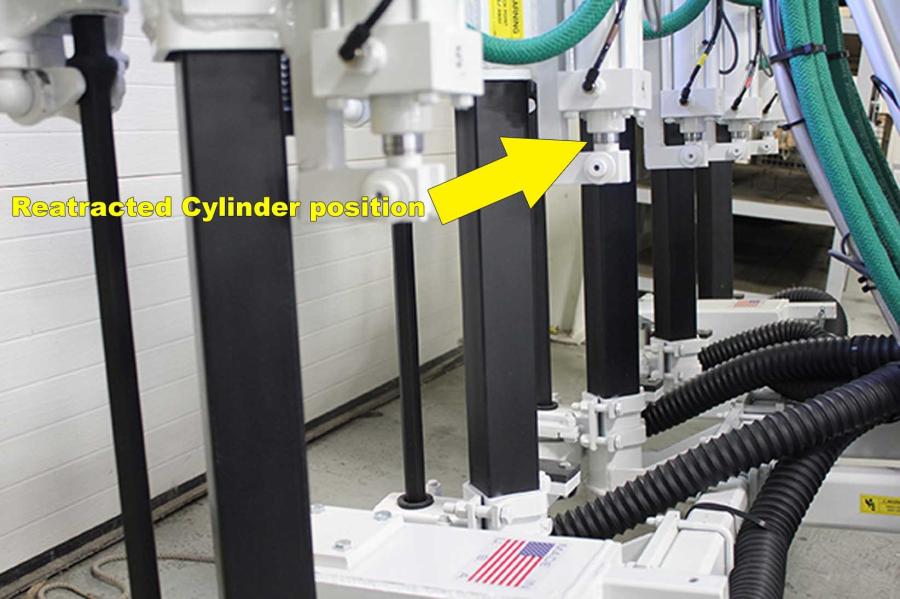

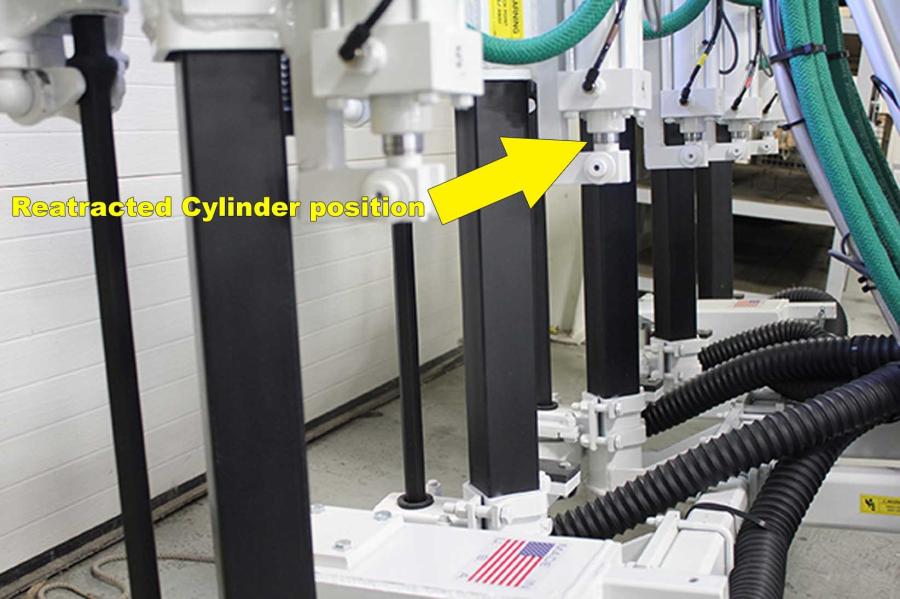

1. Retract all cylinders.

Move all feed and lift cylinders to the retracted position. Retracting the cylinders will prevent the rods from rusting and collecting dust, which damages the cylinder rod seals.

2. Add oil to each drill.

Loosen and remove the air line located at the top of each drill. Pour a capful of oil directly into the air supply line. Reattach and tighten the air supply lines. Turn the main air supply on and then turn each drill valve on for one to two seconds. This will coat the inner parts of the rock drill with oil, preventing rust from forming and seizing up the inner parts of the rock drill while not in use.

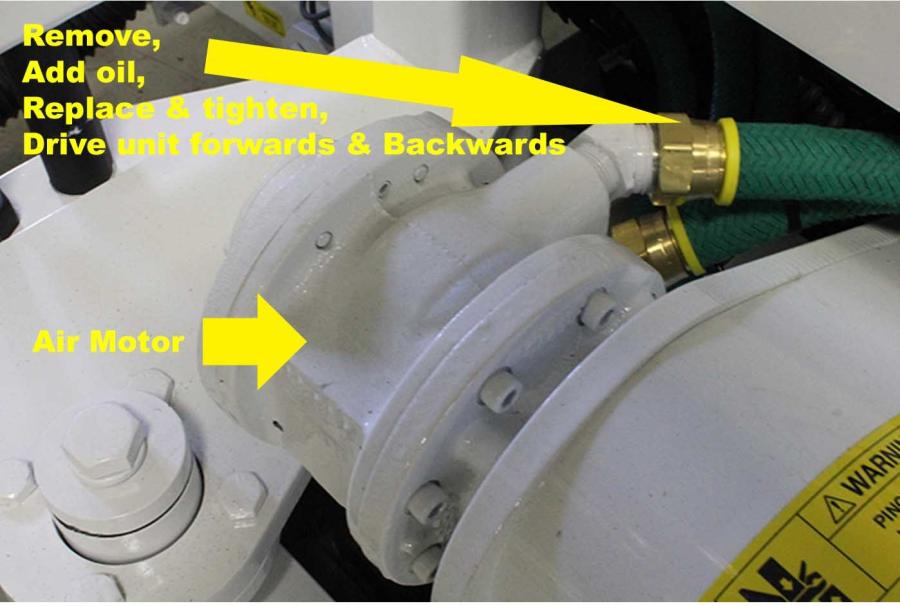

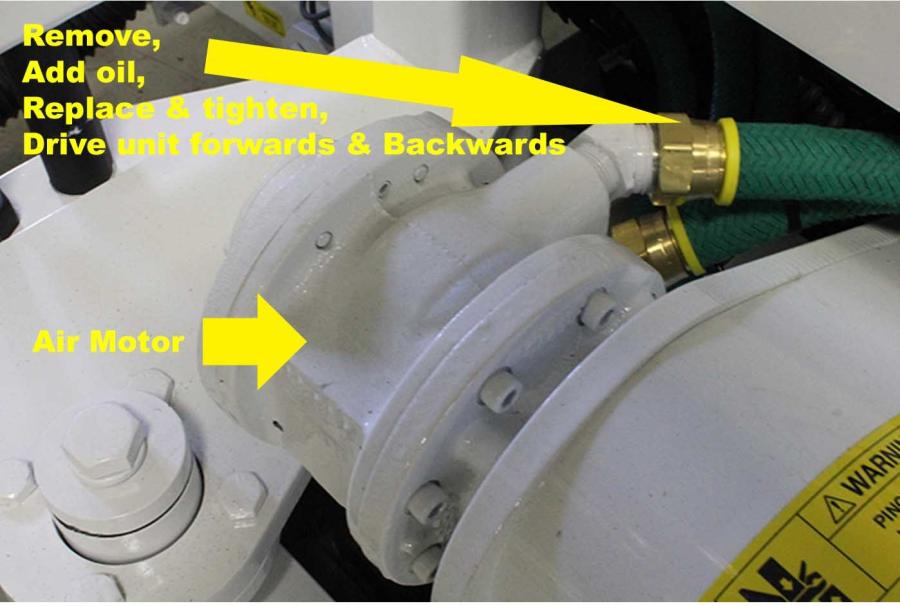

3. Lubricate air motors.

Self–propelled drill units are driven by three air motors. Air motors are commonly replaced due to them seizing up from rust inside the motor. To prevent this, remove the air supply line and pour a pint of rock drill oil directly into the line. Reattach the air supply line to the motor and tighten.

Once you are sure the line is tight, turn on the main air supply and drive the unit forward 5 feet and then backward 5 feet. Repeat this step. This will cause the pint of rock drill oil to completely coat the inside of the air motor, which will prevent rust while the drill unit is not in use.

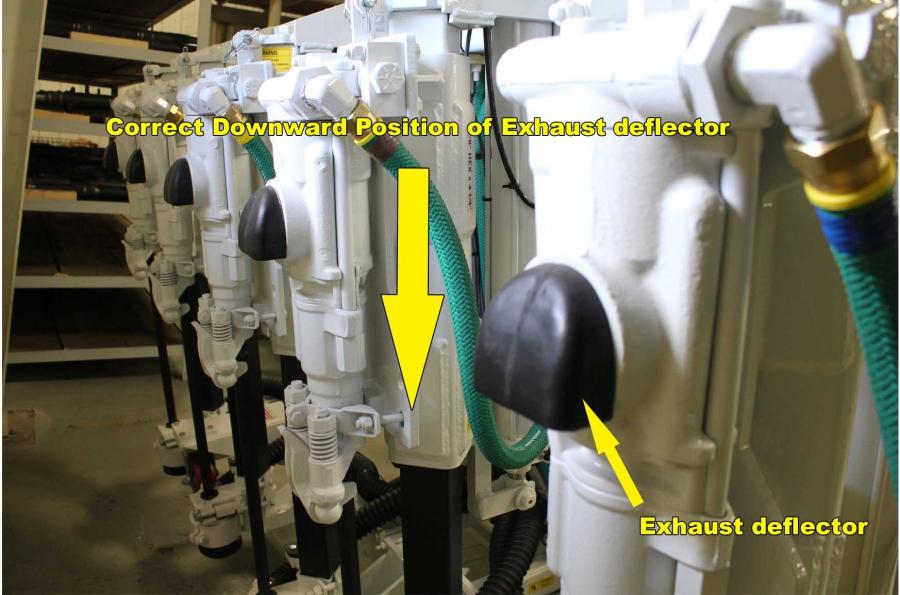

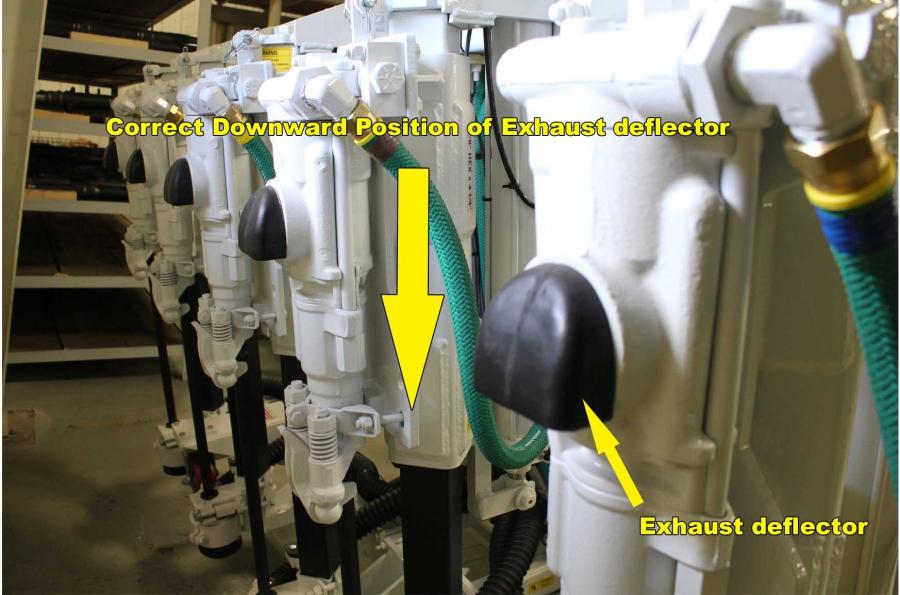

4. Turn down exhaust deflectors.

Make sure that all exhaust deflectors are in the down facing position to eliminate water collecting in the rock drill. Water collecting in the exhaust deflector will eventually make its way into the rock drill itself and lead to rust, causing the rock drill to seize.

5. Top off the oil reservoir.

Fill the oil reservoir with rock drill oil. This will eliminate the possibility of rust forming on the interior of the reservoir.

6. Clean the dust collection system.

Clean the dust collection system's filter and interior canister walls. Indoor storage of the system is recommended, but if outdoor storage is necessary place a plastic bag over the rain caps and secure it in place.

By considering these six tips, companies can help ensure that their dowel-pin drills are ready to drive productivity and profitability when removed from long-term storage.

Send In Paving Vibrators

Sending paving vibrators to the manufacturer for repair early in the winter will help avoid the spring rush, maximize component performance and life span, and avoid costly downtime during the busy season.

Vibrator manufacturers such as Minnich have the equipment and expertise to tear down, inspect, rebuild and test paving vibrators that contractors and dealer partners submit.

Vibrator manufacturers such as Minnich have the equipment and expertise to tear down, inspect, rebuild and test paving vibrators that contractors and dealer partners submit.

When provided with paving vibrators, some of the services Minnich performs include:

- Inspect the bearing/rotor housing for wear. If the bearing/rotor housing thins too much, it could develop a pin hole that eventually causes the vibrator to fail.

- Inspect hydraulic hoses for dry rot or wear. If the outer protective hose wears through, the vibrator will fill up with concrete and will not be easily repaired when service is due.If the hydraulic hose leaks because of corrosion due to exposure from missing outer rubber, the oil will get pumped into the concrete.

- Replace seals and bearings. A worst-case scenario is to have to dig a vibrator out of the static head of concrete while paving because the seals or bearings failed.

- Replace any three-isolator vibrators with a single isolator.The three-isolator bracket gets concrete between the isolators and transfers vibration to the machine instead of the concrete.

- Test the hydraulic motor for slippage. If the motor has some slippage, it will heat up the oil in the system and cause more slippage across the system. That will help speed up the seal wear on the rest of the vibrators.

A vibrator manufacturer or local dealer can estimate the cost of the repairs and let a customer know whether refurbishment or replacement is more cost-effective. Every vibrator that Minnich repairs achieves the same specifications — and carries the same 90-day warranty — as a brand-new one.

A vibrator manufacturer or local dealer can estimate the cost of the repairs and let a customer know whether refurbishment or replacement is more cost-effective. Every vibrator that Minnich repairs achieves the same specifications — and carries the same 90-day warranty — as a brand-new one.

There are some important things contractors should consider doing this winter to maximize drill and paving vibrator performance, manage costs and lengthen product life span. It is important to understand that the preceding tips are general guidelines from Minnich Manufacturing. Companies should always follow storage recommendations from the manufacturer of their specific drills and vibrators.

For more information on Minnich and the Minnich dust collection system, call 419/903-0010 or visit www.minnich-mfg.com.

Today's top stories

Vibrator manufacturers such as Minnich have the equipment and expertise to tear down, inspect, rebuild and test paving vibrators that contractors and dealer partners submit.

Vibrator manufacturers such as Minnich have the equipment and expertise to tear down, inspect, rebuild and test paving vibrators that contractors and dealer partners submit. A vibrator manufacturer or local dealer can estimate the cost of the repairs and let a customer know whether refurbishment or replacement is more cost-effective. Every vibrator that Minnich repairs achieves the same specifications — and carries the same 90-day warranty — as a brand-new one.

A vibrator manufacturer or local dealer can estimate the cost of the repairs and let a customer know whether refurbishment or replacement is more cost-effective. Every vibrator that Minnich repairs achieves the same specifications — and carries the same 90-day warranty — as a brand-new one.