A Komatsu D61PXi dozer with Intelligent Machine control moves dirt on the site of Komatsu Mining’s new headquarters in Milwaukee.

(Komatsu photo)

In Milwaukee, new technology is helping transform an old building site.

The construction of Komatsu Mining Corporation's $285 million headquarters is widely considered a good idea because the redeveloped property will be an attractive addition to the Harbor District. More to the point, it is a smart idea because it showcases Komatsu's Smart Construction technology.

"This is the first time for Komatsu using smart technology to construct a Komatsu facility. It's a demonstration of the technology," said Jason Anetsberger, the company's smart construction senior manager.

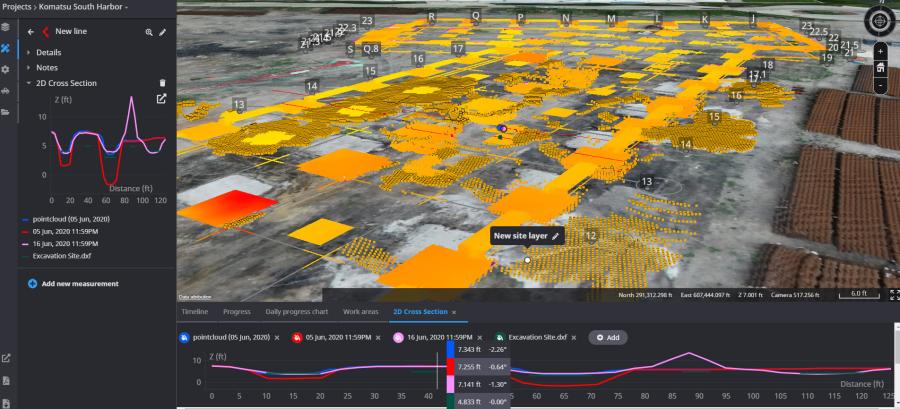

Komatsu excavators and dozers are performing tasks using Intelligent Machine control systems. Drones are providing eyes in the sky and collecting data for the company's Dashboard management system. Managers and crews are getting real-time information from Dashboard so that their 3D plans and management tools always reflect what's happening on the ground.

Heads up: If this sounds like a technology fashion event — a promenade just for show — think again.

"The key thing here is, tech for tech's sake is not a win," Anetsberger said. "You can buy a hundred different apps and not make your life any better. We are using tech solutions that are impactful to the contractor. We've heard from contractors and they want to do more with their manpower, do it more efficiently. They want to replace inefficient processes. That desire for more efficiency is what's driving these solutions."

**

The 58-acre construction site was rendered a brownfield by successive industrial users. Some of its contaminated soil was trucked away during a $16 million cleanup that preceded Komatsu's purchase of the property. What's left must stay on site and poses extra work for general contractor Hunzinger Construction Company, but such working conditions are not unfamiliar to Andie Rodenkirch, Hunzinger's project manager.

"I've been on several sites like this, though this one had a little more to work with," he said. "We have both EPA and DNR regulations that gives us direction on approved contaminant material handling and managing material placement, making sure we don't spread the contaminants to unauthorized locations."

As a practical matter, that means Hunzinger has to account for all material moved from one location on site to another location, ensuring that material being excavated for footings, machine foundations and site utilities is properly relocated and compacted. In short, a whole extra dimension of care is required during the earthwork stage of the job.

Some "smart" tools on site are helping Rodenkirch keep track. Drones being flown by Komatsu engineers as well as by the grading contractor are documenting ground conditions and the transfer of soil from mass grading and excavations to berms. The data and documentation are helping the company meet EPA and DNR requirements.

When deep foundation and excavation of foundation activities ran into unsuspected rubble below ground, obstruction removal activities had to be implemented.

"On average, our footings are six feet down," Rodenkirch said, "but in places we had to go down 14 or 15 feet. Locations clearly had brick and rubble from the early 1900s and we found quite a bit of demolition material — curbing and other concrete debris."

Using Komatsu's Dashboard management technology, the revised excavation parameters were quickly inputted into the 3D project plan. The recalibrated digging depths, material handling schedule and work assignments were outputted to contractors and project architects.

Rodenkirch swears by the Dashboard technology.

"What is really cool is that drone flight surface data is loaded to the dashboard and we very quickly see changes, see the actual progress," he said. "It's been a great tool for us on this site. I have certain locations where I'm allowed to place dirt and am told how much dirt I can put there. I also need to manage the spoil from the various contractors. With Dashboard, I can do all that very quickly."

Ordinarily, Rodenkirch would call up a subcontractor and ask how much dirt was moved. He eventually would have that conversation validated by a materials ticket and at some point, would convert that informal and formal information into hard data that he could share with a project owner.

"Now I can look at the technology and figure out myself where we are on dirt-moving," he said. "I'm not a hundred percent accurate at that moment but it is very close, well within the margin of error and close enough that I can share it with the owner. It's all a lot quicker."

The debris and rubble discovered under the surface couldn't be hauled off site, of course. So, it is currently being stockpiled and eventually crushed for use as base material under the roadways.

"Not only have we eliminated the need to haul off this unsuitable material, this strategy has reduced the overall stone needed for the project," he said.

**

The development includes construction of a three-story, 170,000-sq. ft. headquarters building with a connected two-story training facility and a one-story "customer experience center." A 450-car parking lot will be erected adjacent to the headquarters and on the other side of the property a 410,000-sq. ft. manufacturing facility will rise.

Piles presently are being driven into the ground for the manufacturing building, a months-long process that began in June and was about 40 percent complete in mid-September. In all, some 75 miles of piles will be pounded into the soil as stabilizers.

Footings and foundations are complete for the headquarters building and about a quarter of the building's steel frame has been erected. Pouring of concrete in the parking structure was due to be finished by the end of September.

"Winter is coming so we need to get as much done as we can," the project manager said.

Construction work won't cease when snow begins to fly in Milwaukee.

"We are getting into the months where work doesn't proceed as efficiently as we would like," said Rodenkirch. "Concrete is going to be poured all the way through winter. You just have to put in winter provisions such as using hot water in the mix and blankets to keep the heat in the concrete pour during the initial curing process. We just keep moving forward."

The contractor does stipulate minimum temperatures for doing roofing work for the safety of workers laboring up there.

Some 60 laborers were on site in mid-September, but that number will ramp up to 125 to 150 as exterior and interior work proceed together. Hunzinger will see completion of the job, if the project stays on schedule, by the summer of 2022.

From the point of view of Anetsberger, the showcasing of Komatsu's advanced technology is going well. The various smart tools are proving their worth, as evidenced by Rodenkirch's ease of accounting for the relocation of spoiled material using Dashboard.

"Using pen and paper, it's hard to share and update and distribute information," Anetsberger said. "Once the information is digital and in 3D displays, we can measure our progress and update it quickly as conditions change. Once you get past the hurdle of change, it is so much easier this way to measure and modify and share data."

The bottom line is that the work gets done at lower cost.

"The 3D system is driving cost savings across the industry. Contractors are saving money and project owners are saving money. We are the ultimate customer on this particular site and we're reaping real benefits from our smart technology. It's a win-win for us."

Komatsu Intelligent Machine control is guiding the blades and buckets of dozers and excavators.

"We not only are benefiting from more accurate digging, but also by being able to quickly change our excavation planning when we encounter the unexpected, like all that rubble," said Anetsberger.

And the drones…?

"The site is being mapped on a weekly basis," said Anetsberger. "So instead of walking over soggy ground and dodging construction machinery to gather information, we're using the drones to map it in a fraction of time so we can share the information with contractors."

While the Komatsu headquarters site is relatively small as developments go — think of the hundreds of acres in real estate divisions — Anetsberger believes drones are valuable on any project.

"The bigger the site, the bigger the benefit, but you can realize great efficiencies using the drone regardless of size. Tracking material, for instance, and avoiding disputes about what has been moved," he said.

He believes smart construction technology can pay for itself on a single project "but the biggest benefit for a contractor is the new standard of efficiency that's set. Contractors adopt it for one project, learn what they need to learn and then make it standard operating procedure. We don't want to overload a contractor. We don't want to try to change anyone's world in one leap. Rather, we recommend they try Intelligent Machines first, then a Smart Construction solution and so on. When contractors do it step by step, they have great success."

It is not true that the technology targets big "Class A national contractors," Anetsberger said. "We're interested in providing solutions that can be adopted by big contractors and mom-and-pop builders and all those companies in between."

Hunzinger Construction is pretty big, generating some $325 million in annual business volume. The company's project manager on this project is pretty experienced: He's a 28-year veteran of the industry. Yet this job is the first in which Rodenkirch has utilized the Komatsu Dashboard site management tool and related technologies.

"Will the technology be beneficial for other projects? Absolutely," he said. "We're always looking at new things that will be a good fit for us. Technology that lets an operator stay in the backhoe and constantly dig is so efficient. Bulldozer operators, the same thing. Technologies that let operators do the job one time and do it correctly increase efficiency."

Rodenkirch seems to be enjoying the learning experience and appreciates what Komatsu brought to the project.

"The company has been a real team member and in construction you have to have a team atmosphere to be successful. I think we're a great team," he said.

Anetsberger believes Komatsu "is unique in that we are traditionally all about iron but now we're pairing our equipment with these solutions. We're leading a charge here. We're innovating the industry. We're trying to transform the job site." CEG

Today's top stories