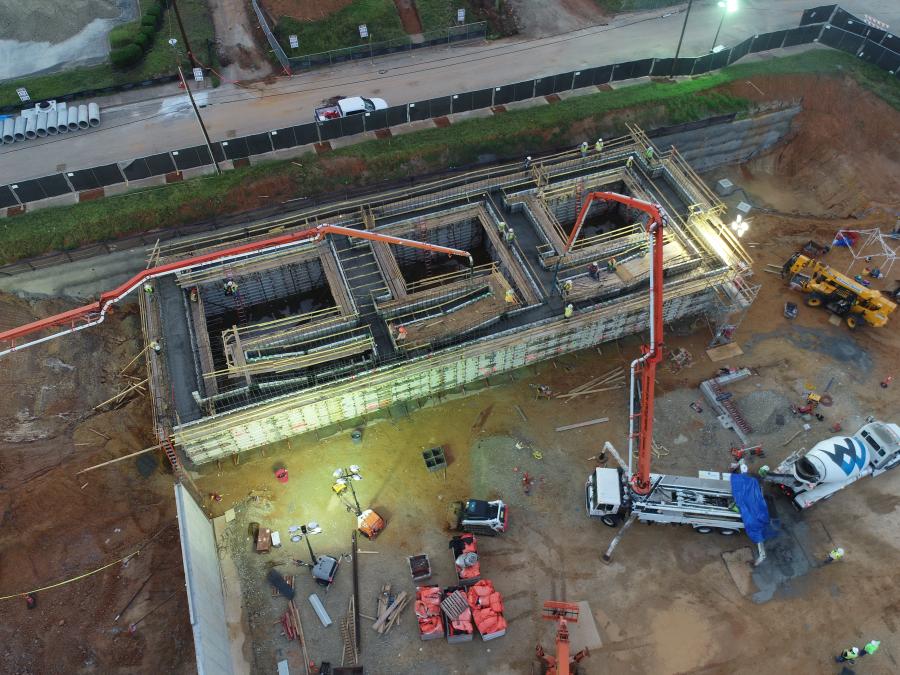

The mass concrete pour for the linear accelerator vault walls at Northeast Texas Cancer and Research Institute called for two concrete pumps, which placed more than 1,100 cu. yd. of liquid-nitrogen cooled concrete in the span of 12 hours. McCarthy self-performed the placement and temperature control.

(Photo courtesy of Martin Montgomery.)

Medical facilities, especially those specializing in cancer treatment and research, pose unique construction challenges. Even more when construction takes place during a heat wave and in the face of post-pandemic supply-chain delays.

McCarthy Building Companies Inc., no stranger to multiphase healthcare and research facility projects, met these challenges head on beginning in May 2021 when it broke ground on the 85,000-sq.-ft., three-floor Northeast Texas Cancer and Research Institute on the CHRISTUS Mother Frances Hospital Campus in Tyler, Texas. The facility is scheduled for completion in October.

Within Northeast Texas Cancer and Research Institute is a CHRISTUS Health 7,500-sq.-ft. Christ Health advanced imaging center equipped with 3 Tesla MRI, PET/CT, ultrasound, x-ray and nuclear medicine. And an additional 10,000 sq. ft. of clinic space will be used to support the surgical oncology programs of Louise Herrington Cancer Center, an inpatient facility located within the Bradley-Thompson Tower at CHRISTUS Mother Frances Hospital, providing advanced inpatient care for cancer patients. The construction also includes a 620-car parking garage.

Such an array of advanced medical technologies requires careful construction of concrete shielding structures as thick as 9 ft. Further, the earthwork performed by McCarthy posed challenges because of the building's position. Built into the side of a hill, there's a 23-ft. difference from one side to the other. This called for the use of layback excavation methods and temporary shotcrete (spray concrete) retention walls to allow for the concrete foundation work to be completed on time.

Not Your Everyday Pour

The project's linear accelerators required massive amounts of concrete. To be exact, 3,065 cu. yds. Two of the pours for the vault walls were 1,100 cu. yd. each, with each taking 12 hours to complete. The third was for the mat slab footing below the walls and took eight hours to complete. Not only were the pours massive, but they also took place during an August heat wave with temperatures topping 100 degrees.

"That's right, we had the bright idea of pouring concrete for the vault walls in the summer," said Martin Montgomery, assistant superintendent of the project.

With American Concrete Institute standards calling for the poured concrete's internal temperature to be 75 degrees, McCarthy used liquid nitrogen in the concrete mix and replaced all the water in the concrete mixers with ice to bring down the concrete's temperature.

"We brought in ice by the truck loads," said Montgomery. "We actually bought out the town's local ice supplier.

"There was a lot of coordination and communication with our ready-mix contractor, Martin Marietta and Mj2 Consulting, which developed the thermal control plans for the continuous concrete pours which ensured leak-proof — and therefore radiation-proof — monolithic structures," Montgomery added.

Big Cs

Coordination and communication were critical components throughout the project, said Montgomery. Case in point: the coordination required of the construction and design teams as the underground plumbing and electrical components were installed well before completion of the tenant improvement (TI) packages.

"The TI packages, which included all the interior build-out drawings — architectural, mechanical, plumbing, electrical, etc. — weren't even issued until October 2021, months after completion of the medical office building's cast-in-place concrete. The foundations were completed in July 2021. This required daily coordination of the utility feeds, plumbing vents and drains inside the walls that were still being designed to ensure components worked properly as they were being installed and that no utilities were interrupted during the site demolition."

Then there were the supply-chain issues.

"Ours started with rebar and cement availability and parts such as metal studs, whose lead times jumped from two to 16 weeks," Montgomery said. "Throughout the project, we were able to identify the long-lead procurement issues and work around them while avoiding design changes that impact procurement. We're still tracking on time because we were able to prioritize."

About Northeast Texas Cancer, Research Institute

The Northeast Texas Cancer and Research Institute, a joint venture of Texas Oncology, an independent oncology practice and CHRISTUS Health, a Catholic not-for-profit healthcare service provider, includes 30,000 sq. ft. of Texas Oncology clinic space for medical, radiation and gynecologic oncology services, and nearly 3,000 sq. ft. dedicated to research. Equipment includes three linear accelerators for radiation therapy and 52 chemotherapy infusion stations, including six for research. Also: four private rooms, pharmacy and lab services and a patient exercise area.

McCarthy's Work in Texas

McCarthy's portfolio of healthcare projects includes the Parkland Moody Center for Breast Health in Dallas, CHRISTUS Spohn Hospital in Corpus Christi and the Alkek Tower and Pavilion expansion at the University of Texas MD Anderson Cancer Center in Houston. CEG

Project At a Glance

Manpower: 65 McCarthy team members, plus another 115 representing 52 subcontractors;

Materials: 2,200 cu. yds. of concrete;

Equipment:

- Kobelco SK350LC-10 excavators (2);

- John Deere 300G LC excavators (2);

- John Deere 650 series dozer (2)

- JLG 1255 telehandler (1);

- JCB 512-56 telehandler (1);

- Takeuchi TB290 mini-excavator (2);

- Bobcat T76 skid steer (2);

- Case wheel loader 521G (1);

- John Deere 332 series skid steer (2);

- Kobelco CK2750G crawler crane (1);

- Tadano ATF 1306 mobile crane (1);

- Link-Belt LS218H crawler crane (1);

- JLG 660 SJ boom lift (6); and

- JLG 860 SJ boom lift (1).

Today's top stories