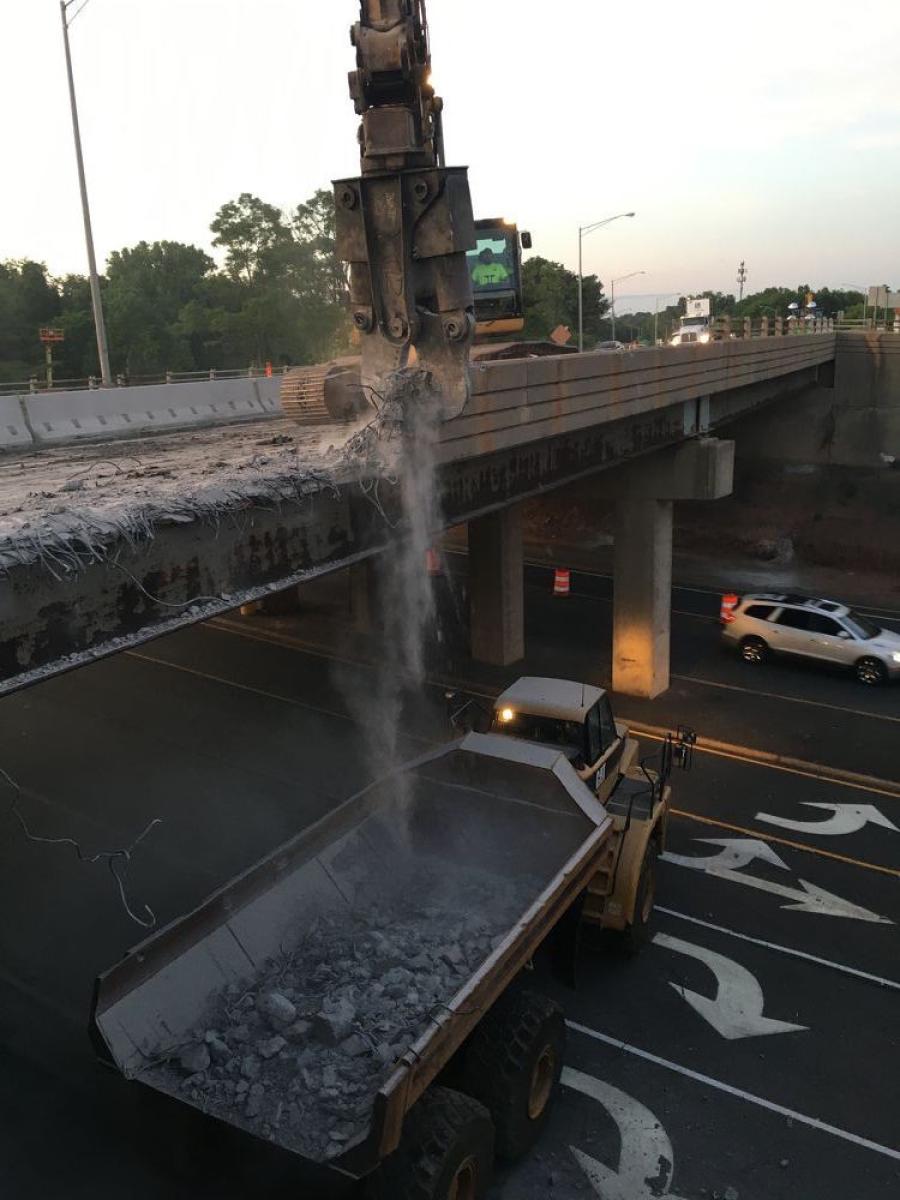

Crews remove the existing steel bridge rail utilizing a backhoe-mounted shear.

The Connecticut Department of Transportation's (CTDOT) $54.6 million I-84 Safety and Operational Improvements project in West Hartford, awarded to O&G Industries Inc., is based upon the mitigation of traffic congestion and safety concerns that can arise in heavy traffic situations.

This two-stage project, financed by the state and designed by BL Companies, started in March 2020 and should be completed in summer 2023. Additional parties involved in the project include Urban Engineers Inc., hired as the construction engineering and inspection consultant.

The project runs west and east along I-84. From the west, it begins at the Farmington/West Hartford town line and ends at the Park Road on-ramp and from the east and 500 ft. east of the Ridgewood Road overpass and extends 200 ft. east of the Mayflower overpass.

Ghazi Alsaqri, CTDOT's project engineer, addressed the initiative's benefits and positive impacts.

"The existing traffic volume within the project limits is at or near capacity, and combined with closely spaced interchanges, results in congestion and weaving concerns on this section," he said. "A review of the three-year crash data between 2012 and 2014 revealed a total of 159 crashes with 48 injuries and one fatality on I-84 WB, and a total of 202 crashes with 90 injuries and one fatality on I-84 EB. The crashes seen most prominently in this time period — rear endings, sideswiping, fixed-object crashes — are indicative of issues related to congestion and vehicle weaving maneuvers.

"The region has grown and with that, the foundations built previously are no longer feasible for the increased volume," he added. "I-84 was constructed in the early 1960s to support regional mobility and commerce; and as the region has grown over the past 60 years, so has daily traffic. Upon its completion, the sections being improved will achieve project goals of increased commuter safety, local and regional commerce and freight mobility."

An additional lane is being added on I-84 WB between Exits 39A and 43, which extends 9,500 ft. Additionally, for the I-84 EB direction, a lane will be added between Exit 40 and 41, which extends 2,800 ft. The lane additions in both directions are feasible via the replacement of the Berkshire Road bridges to accommodate them.

The work also covers replacing the superstructure and widening the Ridgewood Road Bridge on I-84 WB; removing the concrete haunches on the underside of Bridge No. 1747 carrying South Main Street over I-84; installing a noise barrier wall at Bridge No. 1746 carrying I-84 over Rockledge Brook; removing and reconstructing noise barrier walls; and installing an incident management system/information technology system and highway drainage improvements.

Due to regional and population growth, the standards and guidelines for projects of this nature also have changed.

"To ensure that all required standards are met, several elements related to the existing highway cross section, including shoulder widths, will be part of the safety improvements," said Alsaqri. "Guidelines and adherence to standards are being brought up-to-date with the mill and overlay of the existing travel lanes, installation of guiderail to current standards and concrete barrier curb where warranted, relocation of overhead and side mounted sign structures, minor relocation of highway luminaires and the replacement of existing noise barrier walls in poor condition and installation of new ones where warranted."

The construction plan is based on design and engineering issues.

"Construction staging of the bridge replacements is challenging but made possible through temporary closure or realignment of I-84 EB and WB Exit 40 on-ramps," said Alsaqri. "The Ridgewood Road Bridge for I-84 WB is a two-span steel girder bridge and both Berkshire Road bridges are single-span steel girder bridges. The new structures at Berkshire Road are innovative Geosynthetic Reinforced Soil-Integrated Bridge Systems [GRS-IBS], which are typically less expensive and faster to build, and the reinforced approach roadway alleviates the bump at the bridge typically caused by differential settlement."

The noise barrier walls will be constructed during Stage 2, when traffic is shifted to the inside of the highway, to meet current engineering standards and reduce roadway noise for adjacent residents and businesses.

"During the planning and design phase, the department conducted a noise study in accordance with Federal Highway Administration requirements for this type of project," said Alsaqri.

CTDOT is keeping people informed about traffic and construction updates through social media platforms and public meetings.

"Construction activities are being performed during periods of lighter traffic volumes and three lanes will be maintained in each direction during all heavy traffic periods," according to CTDOT. "In order to reduce the impact [of] lane closures, certain activities will be required to take place at night. Construction activities can occur at any time. However, the allowable lane closure periods are restricted to minimize impacts to the travelling public."

Stage 1A of the project, which was just completed, dealt with the first half of the I-84 WB bridge at Ridgewood and median reconstruction at the western limits of the project, and Stage 1B, which should be finished in April 2022, covers portions of the new Berkshire Road Bridges, median widening, cross slope correction, and retaining walls.

Stage 2A, from April to October 2022, will focus on the second half of the I-84 WB bridge over Ridgewood Road, outside shoulder reconstruction, noise barrier walls, and the remaining portions of the Berkshire Road bridges, while Stage 2B — November 2022 to May 2023, focuses on implementing the final traffic patterns and removing temporary pavement used during staging of the project.

"Every job has different challenges," said John Rouleau, O&G's project manager. "CTDOT is in the midst of re-profiling its roadways — not just taking roadways and overlaying them, but putting in new cross slope and profile changes. One of the first operations on this project was laser scanning the entire roadway, then overlaying that data onto the new proposed cross sections. With this information, we were able to compute the cut and fills to the proposed roadway riding surface. Next, we milled the existing roadway to remove the deteriorated asphalt, fills were laid out and multiple lifts of bituminous concrete were placed to bring the roadway to its proposed new grade.

"This presented an early challenge because the paving needed to occur prior to work starting on the first milestone operation, which was the Ridgewood Road Bridge that had a Stage 1A completion date of October 2020," he added.

"We had to complete this wedge paving, which required a great deal of finesse and was time consuming. We started on the demolition of the Ridgewood Road Bridge in June and completed the Stage 1A portion of the bridge work on schedule, which was critical to CTDOT and us.

"Relations with CTDOT and their designers are one of the best I have encountered in my 35-year career. There are always issues, but they have been proactive in working with us. If we had any submittals that were red lining, they put their utmost attention to turn it around as soon as possible."

Another key operation involves the placement of the Information Management System (IMS). This includes the installation of cameras, message boards and underground fiber optic cable in ducts. This had to be completed prior to the start of the bridge reconstruction on Ridgewood Road and Berkshire Road.

"We are presently in discussions of how to expedite the IMS scope to enhance the schedule," said Rouleau, who noted that there have been no major issues from a utility standpoint. "CTDOT coordinated all of the utility work needed to make sure the Stage 1 work on the Berkshire Road Bridge was completed on time."

The initial night work wrapped up in early December.

"These operations revolved around the re-profiling of the road," said Rouleau. "We will be working through the 2020-2021 winter. There will be times when we slow down certain operations. We won't be doing any paving, but there will be some concrete work, setting precast barriers, bridge demolition, abutment construction, drainage installation and earth work that will continue.

"Right now, we're working in the median section — egress is a challenge and we have been using the ends of the job and Berkshire Road as ways of entering and exiting," he added. "As we build the bridges on Berkshire Road, access to the median will soon be closed off so all egress will be at the east end of the job. This will allow us to work safely and effectively during the day. It's tight, but doable."

O&G crews are now in Stage 1B.

"The roadway is being widened and we're placing 10 inches of processed aggregate base on a compacted subgrade, then topping it with 15 inches of asphalt," said Rouleau. "This asphalt is comprised of several layers of polymer modified asphalt [PMA]. The road work has started in the median. We did all of the Stage 1A road work and quite a bit of the median on the western limits of the project. Presently, we're working on Berkshire Road Bridge toward the eastern limits of the project. Our goal is to get everything graded so that in April or May, we can start paving right away."

Currently, the day and night shifts have been between 50 and 70 craft personnel, including the laborers, carpenters, ironworkers, Operating Engineers, Teamsters, electricians and masons.

The Ridgewood Road Bridge (1743) is 150 ft. long and has two spans and the Berkshire bridges (1744 and 1745), approximately 90 ft. long, are being converted to single span bridges.

"They will be built on Geo-Synthetic Reinforced Soil [GRS] abutments, and each of the bridges are being done in two phases," said Rouleau. "They will be worked on simultaneously. We wrapped up the demolition of the median sections for bridges 1744 and 1745. For bridge 1743, we're modifying the abutments, the piers and putting in architectural in-fills below it."

A shear mounted on a Caterpillar 345 backhoe is helping with the demolition activities.

"We're using GPS equipment to assist grading and drainage operations, and have GPS systems mounted to our dozers and backhoes," said Rouleau.

The asphalt removed by milling operations is immediately placed in trucks and brought to a plant where it is recycled to create RAP. The concrete from the bridges is taken to recycling plants where it is crushed and turned into subbase.

"We're recycling quite a bit of the material," said Rouleau.

Nearly 5,000 ft. of new noise barrier wall shall be installed in Phase 2, toward the end of 2021 and into 2022.

"It is anticipated it will reduce highway noise by about 20 decibels," said Rouleau. "We're replacing dilapidated walls with columns augured into the ground, stabilized with concrete,and sound absorption panels with an ashlar stone to finish it."

Rouleau has a solid management team and seasoned crews.

"Our team is a quality group, most with over 20 years of roadway and bridge building under their wing," he said. "CTDOT and Urban Engineers also have a strong team. Urban Engineer's Josh Gray is an excellent resident engineer — he's very thorough and a pleasure to work with. You need a good team pulling in the same direction and sharing a common goal to build a quality successful project. I've also been very satisfied with the people that the unions sent to us.'

The main subcontractors are Langan Connecticut Inc. for road scanning; CCA LLC. for surveying; Tilcon Connecticut Inc. for milling and paving; AFC Construction LLC. for the concrete work on the bridge structures; A.M. Rizzo Electrical Contractors Inc. for electrical, light, signal and IMS work; Alma Iron LLC. for furnishing and installing rebar for the bridges; Quaker Corporation for the overhead and side-mounted signs; Haven Steel Erectors Inc. for the bridge steel; Supreme Industries Inc. for the clearing and grubbing; Total Fence LLC. for the metal beam rail and protective fencing; and Safety Marking Inc. for the pavement markings.

Bridge demolition, along with other activities, should generate 3,500 cu. yds. of concrete removal; 10,000 tons of bituminous concrete removal; 900 tons of structural steel removal; and 56,900 cu. yds. of earth and rock excavation.

New construction materials should include: 4,000 cu. yds. of concrete; 68,500 tons of bituminous concrete; 800 tons of new structural steel; 80 new drainage structures and 6,600 linear ft. of drainage pipe.

Additional equipment on site and to be brought in later includes: a Grove RT880E rough-terrain crane; Caterpillar backhoes — an M322F, a 335F, two M330s and a 345 backhoe with a LaBounty UP 45 processor; two Caterpillar D6 dozers; a JLG 60-ft. manlift; an Ingersoll-Rand SD116DX earth roller; a Caterpillar 966E loader; a Sterling LT9513 tri-axle dump truck; and a Kenworth T800B truck.

"We have an onsite mechanic to take care of issues that can be handled here," said Rouleau. "If it's something major, it's removed from site and replaced. We maintain the equipment daily — proper grease and oil changes, hose condition checks are conducted by both the operators and the mechanics. The operators check the fluid levels prior to starting the equipment each start of shift and the equipment must be cleaned at the end of each shift. It's attention to detail, upkeep and daily maintenance that allows our operations to stay efficient." CEG

Irwin Rapoport

A journalist who started his career at a weekly community newspaper, Irwin Rapoport has written about construction and architecture for more than 15 years, as well as a variety of other subjects, such as recycling, environmental issues, business supply chains, property development, pulp and paper, agriculture, solar power and energy, and education. Getting the story right and illustrating the hard work and professionalism that goes into completing road, bridge, and building projects is important to him. A key element of his construction articles is to provide readers with an opportunity to see how general contractors and departments of transportation complete their projects and address challenges so that lessons learned can be shared with a wider audience.

Rapoport has a BA in History and a Minor in Political Science from Concordia University. His hobbies include hiking, birding, cycling, reading, going to concerts and plays, hanging out with friends and family, and architecture. He is keen to one day write an MA thesis on military and economic planning by the Great Powers prior to the start of the First World War.

Read more from Irwin Rapoport here.

Today's top stories