Both bridges, with an expected design life of 75 years, will be open to traffic in October 2021.

SPS New England Inc. started work on the Massachusetts Department of Transportation's (MassDOT) $102 million I-495 Haverhill Bridge Replacement Project that is replacing and widening existing north-south bridges spanning the Merrimack River in Haverhill.

The old bridges, built in 1961 — 712 ft. long, three lanes in each direction and shoulders on either side — are being replaced to address structural and functional deficiencies. The design-build project, funded by federal (80 percent) and state (20 percent) dollars, began in August 2018 and will be fully delivered in June 2022.

The work zone extends from approximately Exit 48 south to Exit 49 north of the bridges. The new bridges will be 718 ft. long.

The southbound bridge will include an 8-ft. shoulder adjacent to the median, a 12-ft. shoulder on the outside of the roadway, three 12-ft. travel lanes and a 12-ft. lane reserved for potential future widening. The northbound bridge will include a 6-ft. shoulder adjacent to the median, a 10-ft. shoulder on the outside of the roadway, three 12-ft. travel lanes, a 12-ft. auxiliary lane, and a 12-ft. lane reserved for potential future widening.

The project also includes: localized widening and reconstruction of ramps, roadway realignment, safety improvements, roadway drainage system improvements, pier protection barrier for existing bridge piers at interchange 48 and 49, signage and pavement marking improvements, utility relocation, landscape restoration and wetland mitigation.

The construction has been divided into four stages, with Stages 1 and 2 (September 2018 to August 2020) covering the demolition and reconstruction of the northbound bridge, Stage 3 will see the southbound crossover completed this August and the demolition and reconstruction of the southbound bridge by September 2021, and Stage 4 (September 2021 to June 2022) deals with the median restoration.

Both bridges, with an expected design life of 75 years, will be open to traffic in October 2021.

"The bridges were in disrepair and had reached the end of their lifespan requiring frequent repairs " said Kristen Pennucci, MassDOT's communications director. "The new bridges will eliminate need for constant emergency repair work, improve roadway safety, provide motorists with full-width breakdown lanes, create a dedicated exit lane for northbound exit 49, modify the existing alignments and increase the width for the acceleration lanes. Planning for the project began in 2012. The need was obvious to anyone traveling the highway and it has support from local and state elected officials and the public."

A key piece of equipment for the construction has been a 275-ton crawler crane placed on the trestle and flexifloat platform in the water.

"The crane has serviced all aspects of construction, including drilled shafts, demolition and structural steel erection," said Pennucci.

Regina Villa Associates Inc. is handling the project's public outreach for MassDOT, which included a well-attended public meeting August 2018 meeting to discuss the project.

HNTB, the lead designer, designed the new bridges and roadwork to accommodate the phased construction plan. The bridges are going from five to three spans, which reduce future maintenance costs.

"With all of our bridges, the long-term durability of joints in bridge deck is a constant concern," said Pennucci. "These joints are where the bridge tends to degrade first, which can lead to the need for frequent maintenance. The new bridge features a continuous deck, eliminating the need for intermittent bridge joints. This should increase the longevity of the structure, reduce maintenance costs and improve the ride quality."

Green International Affiliates Inc. was responsible for the survey, drainage and structural design.

To protect the Shortnose and Atlantic sturgeon, work restrictions have been put in place to protect the fish during the spawning period and before they migrate out of the river. In-water work is restricted each year to a small window from November to February.

SPS New England crews are currently building the eastern half of the new northbound bridge. Prior to the replacement, the bridges carried 115,000 vehicles daily and the new ones will carry 127,000 per day.

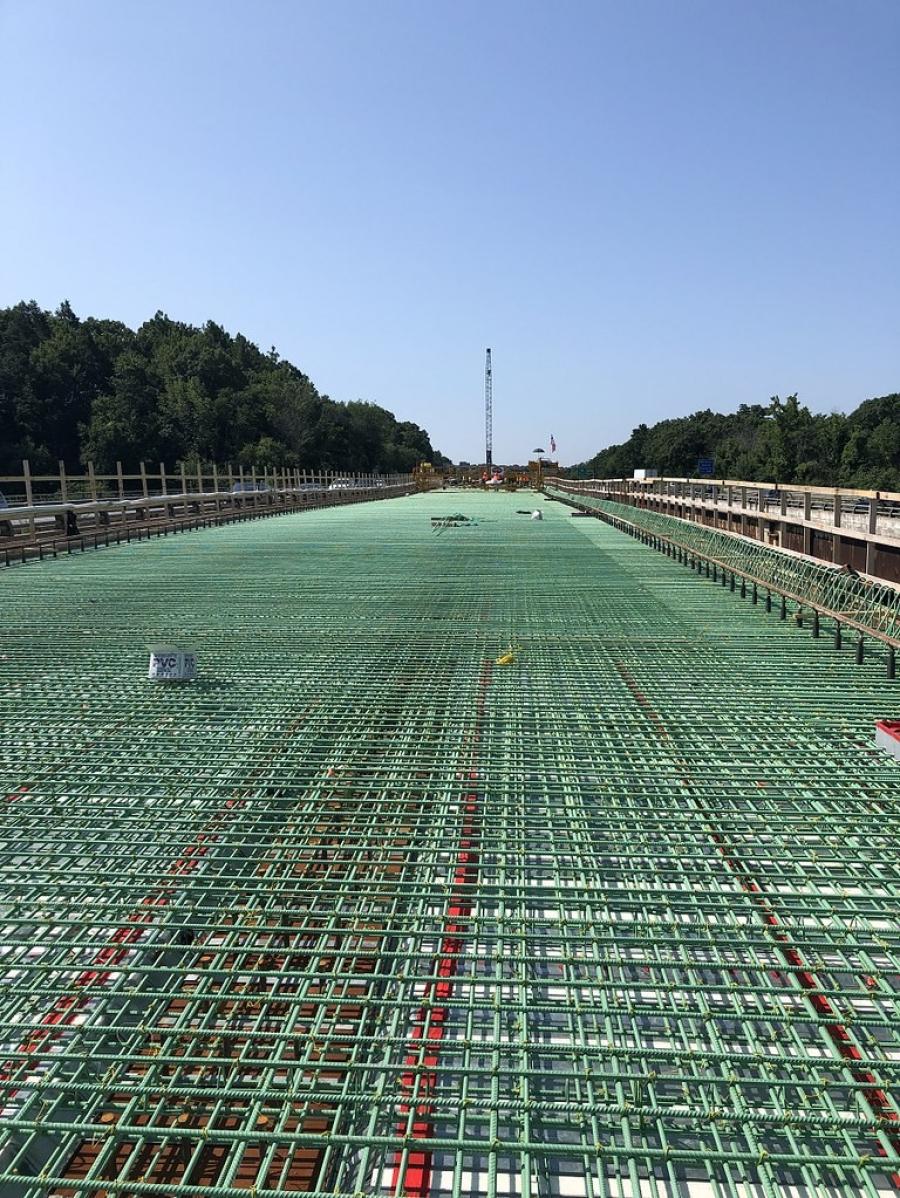

"The substructure work is complete, and the contractor recently completed erection of the Phase 2 structural steel," said Pennucci. "Work over the summer will focus on the superstructure of the bridge, which includes forming and placing the bridge deck and barrier along with building the new roadway approaches to the bridge structure. Ongoing median work includes the pier protection barrier for the River Street and Industrial Avenue overpasses. Phase 2 work will continue throughout the summer."

The project is not without its challenges.

"Working over the river with tidal and seasonal flow variations along with tight in water work windows are among the challenges," said Jacqueline Goddard, MassDOT's assistant secretary of marketing and communications. "Currently crews are only working during the day. Depending on the operation, crews have and will continue to work nights and weekends to maintain schedule and to facilitate lane closures for operations such as beam erection and paving. Access to the work zone has been difficult. However, the staging area at Bank Road combined with the trestle system has been very useful, aiding in access to the work area."

There are existing sewer lines on either side of the bridge.

"Vibrations are monitored around these sewer lines throughout construction, and camera inspections are performed before and after construction to ensure the project has had no effects on the performance of these sewer lines," said Goddard.

Safety briefings are held each morning to coordinate operations between trades and various subcontractors.

"In addition to daily safety meetings," said Goddard, "tool-box talks are held regularly to discuss typical safety challenges on site as well as frequent ‘man-overboard' drills simulating the safety protocols and response should a worker fall into the water."

The northbound bridge will be completed in October 2020.

"A median crossover was constructed and the northbound bridge demolished so the new bridge could be constructed," said Pennucci. "Once complete, all six lanes of northbound and southbound traffic will be shifted to the new northbound bridge and the southbound bridge will be demolished and a new bridge constructed in its place. A nearly identical process will be utilized for the construction of the southbound bridge."

The demolition of the old northbound bridge began October 2019

"The poor condition of the existing bridge required the use of the small excavators to demolish the existing deck," said Goddard. "The short window for in-water work proved challenging to complete substructure demolition. The underside of the existing deck was shielded to prevent debris from falling into the river."

The demolition debris that can be accessed during normal business hours is direct loaded whenever possible.

"For night work or areas with limited access due to lane closures, debris was stockpiled outside the limits of the bridge and loaded out when access was available," said Goddard.

The barges, ranging from large to smaller sizes, are capable of handling large cranes and many construction workers, as well as building materials and materials removed during the demolition and construction phases. Tugs allow for the barges to be moved to various locations and be connected to create larger work platforms.

Temporary navigational lighting to USCG standards has been installed to support the efforts on the water.

The road work, safety improvement, drainage work and other ancillary elements are proceeding as scheduled. A large section of the median was converted into a staging area to store building materials and bring equipment in and out.

"Everything is on schedule," said Pennucci.

The amounts of concrete and steel to be generated by the demolition of the old bridges is still being tabulated. The excavation work should generate 160,000 cu. yds. of earth and 35,000 tons of pavement.

"Existing pavement was reclaimed on site and mixed with existing soils to develop a roadway subbase material," said Goddard. "Concrete from demolition activities was shipped off site to a local recycling facility where the rubble was crushed and turned into a recycled concrete gravel borrow like material."

New building materials should include 7 million lbs. of structural steel, 3.5 million lbs. of temporary steel and 15,000 cu. yds. of concrete.

Peak days have 40-plus SPS and subcontractor (local and regional) employees on site

SPS is using: cranes, excavators, dozers, loaders, pavers, rollers, barges, tugs, a variety of small boats used by crews, and other standard construction equipment.

The firm purchases and rents equipment from local and regional dealerships. CEG

Irwin Rapoport

A journalist who started his career at a weekly community newspaper, Irwin Rapoport has written about construction and architecture for more than 15 years, as well as a variety of other subjects, such as recycling, environmental issues, business supply chains, property development, pulp and paper, agriculture, solar power and energy, and education. Getting the story right and illustrating the hard work and professionalism that goes into completing road, bridge, and building projects is important to him. A key element of his construction articles is to provide readers with an opportunity to see how general contractors and departments of transportation complete their projects and address challenges so that lessons learned can be shared with a wider audience.

Rapoport has a BA in History and a Minor in Political Science from Concordia University. His hobbies include hiking, birding, cycling, reading, going to concerts and plays, hanging out with friends and family, and architecture. He is keen to one day write an MA thesis on military and economic planning by the Great Powers prior to the start of the First World War.

Read more from Irwin Rapoport here.

Today's top stories