The Super 3000-3(i) is the new flagship in Vögele’s paver line-up and a representative of the newly introduced premium line.

Vögele has restructured its product range and is poised to stage several premieres: the Super 3000-3(i), the biggest paver in the company's product range, the Super 1000(i) and 1003(i) compact pavers, the SB 300 and SB 350 fixed-width screeds, and the new functions of the WITOS paving process-management solution.

To help customers find their way around the large range of different pavers, Vögele restructured its product range at the end of last year, dividing it into two lines: the Classic Line and the Premium Line. Classic Line products are equipped with the ErgoBasic operating system, Premium Line products with the ErgoPlus operating system.

Within the lines, the company again differentiates between the previous five classes of mini, compact, universal, highway and special class.

"At bauma 2019, we will be showcasing the latest models from both lines for the first time," said Roland Schug, head of marketing at Vögele.

"The Classic Line pavers offer all the basic features required for high-quality paving, while the Premium Line machines come with the added features of the 'Dash 3' generation," said Schug.

These include the automatic functions of AutoSet Plus, the PaveDock Assistant communication system and the Vögele EcoPlus low-emissions package.

Premium Line: The Super 3000-3(i), Vögele's New Flagship

The latest and most prominent representative of the Premium Line is the Super 3000-3(i). With a pave width of up to 59 ft. (18 m), a laydown rate of 1,984 ton (1,800t) per hour and an engine output of 354 kW, it is the new flagship in VÖGELE's paver line-up. It is not only suitable for medium-sized construction projects and the rehabilitation and construction of motorways, but also for paving airport runways, large squares and traffic areas.

Due to the new material transport system, the paver can now install thin surface courses as well as base courses of up to 19.6 in. (50 cm) thick — without any mechanical conversion work: machine operators can infinitely adjust the height of the rear section of the chassis, along with the conveyor and auger, at the push of a button. As a result, material can always be transferred to the auger from above, guaranteeing an optimum head of mix regardless of layer thickness, according to the manufacturer.

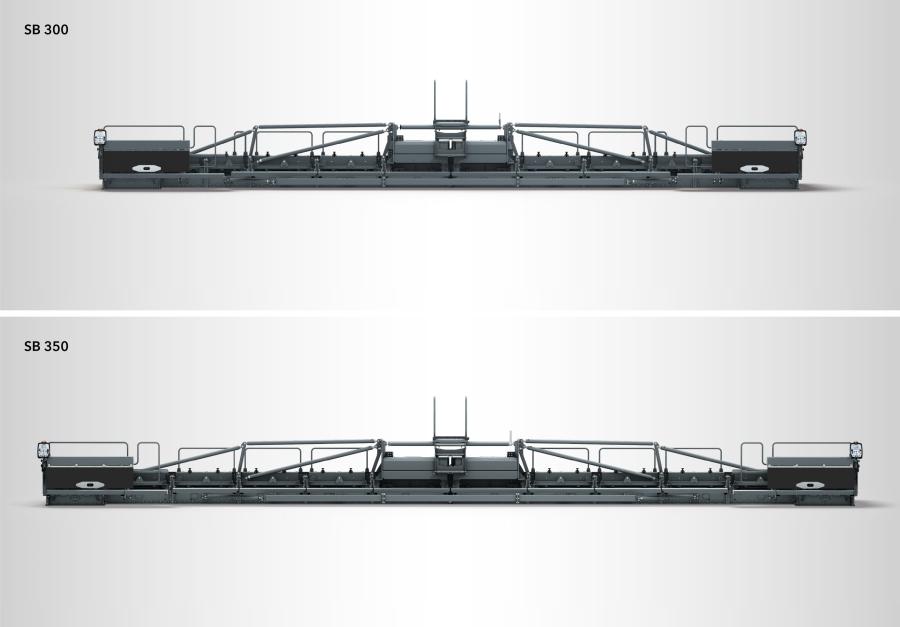

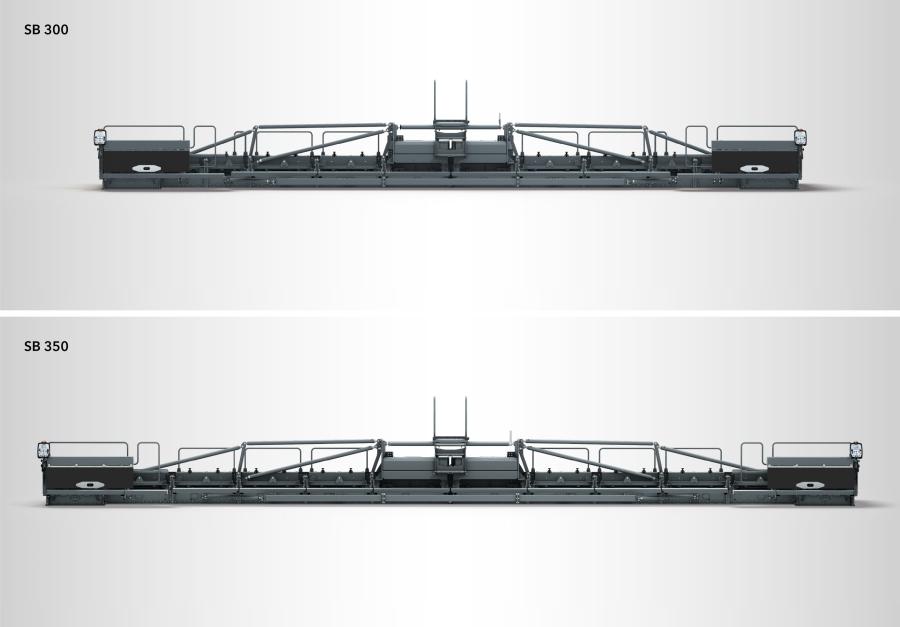

The New SB 300 and SB 350 Fixed-Width Screeds

The New SB 300 and SB 350 Fixed-Width Screeds

At bauma, Vögele also will be presenting two highlights from their screed program to go with the Super 3000-3(i): the new SB 300 and SB 350 fixed-width screeds. Both models offer a wide range of user-friendly innovations and the SB 350 supports potentially record-breaking pave widths of up to 59 ft. (18 m).

The possibility of hydraulically adjusting both screeds by up to 8.2 ft. (2.5 m) with the newly developed hydraulic bolt-on extensions is a globally unique feature. This guarantees high flexibility during paving. In addition, a special telescoping and positioning system reduces the set-up times when mounting the fixed bolt-on extensions.

Another advantage for operators is that the tamper stroke can now be adjusted hydraulically when required, i.e. simply by pressing a button on the paver operator's or screed operator's console. This speeds up processes, especially when working with varying layer thicknesses.

Both screeds also are equipped with a new heating system that heats the screed plate, tamper and pressure bars 50 percent faster than before and much more uniformly, according to the manufacturer.

The SB 300 replaces the SB 250 and can be combined with the Super 1800-3(i), the Super 1900-3(i), the Super 2100-3(i) and the Super 3000-3(i). The SB 350 was specially designed for the Super 3000-3(i).

World Premiere for Four Classic Line Pavers

World Premiere for Four Classic Line Pavers

Vögele is presenting four new products from its Classic Line at bauma: the Super 1000(i) in the tracked version and the Super 1003(i) in the wheeled version, as well as the Super 1600 and Super 1603.

The two Super 1000(i) and 1003(i) compact pavers comply with the European emissions standards Stage 4 (or 3a in the case of machines without the "i" suffix) as well as the U.S. standards EPA Tier IVf (or 3 in the case of machines without the "i" suffix). With a maximum pave width of 12.8 ft. (3.9 m), they are particularly suitable for small and medium-sized projects on municipal job sites as well as for landscaping applications.

They can be combined with the AB 340 extending screed in the TV version (with tamper and vibrators) or the V version (with vibrators). The Super 1600 and 1603 universal class pavers meet the European emissions standards Stage 3a and the U.S. standard EPA Tier III.

With their 116 kW diesel engine and a laydown rate of up to 661 ton (600 t) per hour, they are extremely powerful, robust and versatile, whether they are working on confined urban job sites or constructing rural roads or motorways. When combined with the AB 480 extending screed with the tamper and vibrator (TV) compacting systems, the pavers can achieve a maximum pave width of 20.6 ft. (6.3 m).

All four Classic Line machines also are equipped with the intuitive and clearly structured ErgoBasic operating concept, which provides users with all the functions they need to achieve high-quality paving while giving contractors excellent value for money.

WITOS Paving Docu: Automated Job-Site Documentation

WITOS Paving Docu: Automated Job-Site Documentation

Apart from its latest paver and screed technology, Vögele also will be presenting the latest developments associated with its software-based process-management solution, WITOS Paving, at the upcoming bauma.

Up until now, Vögele has offered contractors two options for recording and evaluating job-site data: the RoadScan non-contacting temperature-measurement system, with which the site manager can monitor the paving temperature; and the WITOS Paving Plus telematics solution, with which all processes from mixing plant to paving can be coordinated in real time and actively optimized.

The latest innovation, WITOS Paving Docu, has been specially developed by Vögele for contractors who want to record and evaluate other data in addition to the paving temperature, but who do not need the full range of WITOS Paving Plus functions including process optimization.

With WITOS Paving Docu and the help of an app, site managers can initiate jobs directly on the job site without prior planning, recording all the paver and paving data. In addition, delivery notes can be scanned in using a QR code or also entered manually and, at the end of the day's paving operations, automated job-site reports can be sent to selected recipients. The app and pavers are networked via WLAN, so that information can be exchanged even without a mobile phone connection.

"Based on their job sites, contractors can now decide whether they only want to use WITOS Paving Docu to document process data for later evaluation, or whether they want to upgrade to the full WITOS Paving Plus version so that they can plan the job site in advance and actively optimize the processes via the system," said Stephan Weller, head of software products at Vögele. "We are hence offering our customers extremely flexible and tailor-made solutions."

For more information, visit www.voegele.info.

Today's top stories

The New SB 300 and SB 350 Fixed-Width Screeds

The New SB 300 and SB 350 Fixed-Width Screeds World Premiere for Four Classic Line Pavers

World Premiere for Four Classic Line Pavers WITOS Paving Docu: Automated Job-Site Documentation

WITOS Paving Docu: Automated Job-Site Documentation